Food trays with lids are indispensable in today’s food industry, playing a crucial role in everything from food storage and transportation to serving and presentation. These versatile containers come in a wide array of materials, shapes, and sizes, designed to meet diverse needs across various sectors, including restaurants, catering services, and food delivery businesses. This exploration delves into the intricacies of food trays with lids, examining their functionality, the materials they are made from, and the impact they have on food safety and the environment.

From the basic design to the intricate manufacturing processes, we’ll uncover the features and benefits that make food trays with lids essential. We will analyze different types, their applications, and the innovative trends shaping their future. The goal is to provide a comprehensive understanding of these everyday items, highlighting their importance in the modern food ecosystem.

Food Trays with Lids

Food trays with lids are essential containers designed to hold and transport food items while maintaining their freshness, temperature, and overall quality. They serve a crucial role in the food industry, encompassing restaurants, catering services, and food retail, ensuring food safety and convenience. These trays are engineered to offer a secure and hygienic environment for a variety of food products, from prepared meals to raw ingredients.

Materials Used in Manufacturing

A variety of materials are employed in the production of food trays with lids, each offering distinct advantages in terms of functionality, cost, and environmental impact. The selection of material is often dictated by the specific application, the type of food being contained, and the desired shelf life of the product.

- Plastic: Plastic is a widely used material due to its versatility, cost-effectiveness, and lightweight properties. Common types of plastic include:

- Polypropylene (PP): Known for its high melting point, making it suitable for hot foods and microwave use. PP is also resistant to chemicals and moisture.

- Polyethylene Terephthalate (PET): PET is a clear, strong, and recyclable plastic often used for cold food items and providing good visibility of the contents.

- Polystyrene (PS): PS is another common material that can be expanded or foamed to provide insulation and cushioning.

- Aluminum: Aluminum trays are excellent for heat conduction and are frequently used in baking and roasting applications. They are also recyclable, adding to their appeal.

- Paperboard/Cardboard: Paper-based trays offer a sustainable alternative, especially when sourced from recycled materials. They can be coated with a food-grade wax or polymer to provide a moisture barrier.

- Foam: Expanded polystyrene (EPS) foam provides excellent insulation, keeping food hot or cold for extended periods. However, foam trays have environmental concerns due to their non-biodegradable nature.

- Biodegradable Materials: Increasing consumer demand for sustainable options has led to the development of trays made from biodegradable materials like plant fibers (e.g., sugarcane bagasse), compostable plastics (e.g., PLA – Polylactic Acid), and other renewable resources.

Sizes and Shapes Available

Food trays with lids are manufactured in a wide array of sizes and shapes to accommodate diverse food products and packaging requirements. This variety ensures optimal portioning, efficient storage, and appealing presentation.

- Shapes:

- Rectangular: The most common shape, suitable for a broad range of foods, from entrees to desserts.

- Square: Often used for single-serving meals, side dishes, and baked goods.

- Round/Oval: Ideal for soups, stews, salads, and other items that benefit from a curved container.

- Compartmentalized: These trays feature multiple sections, allowing different food items to be separated, preventing mixing and maintaining their individual flavors and textures. This is a common feature in bento boxes and ready-to-eat meal trays.

- Sizes: Trays come in a wide range of sizes, measured in length, width, and depth, with common size categories. The specific dimensions are often customized based on the application.

- Small: Suitable for individual servings, snacks, and side dishes.

- Medium: Designed for entrees, larger portions, and family-sized meals.

- Large: Intended for catering, bulk food storage, and events.

- Examples:

- A fast-food restaurant might use a small, rectangular plastic tray for a combo meal, including a burger, fries, and drink.

- A catering company could use a large, compartmentalized tray to serve a variety of dishes at an event.

- A supermarket may utilize a medium-sized, clear PET tray to package pre-made salads.

Types of Food Trays with Lids

Food trays with lids are essential for food storage, transportation, and presentation. The choice of tray and lid often depends on factors like the type of food, desired level of protection, and environmental considerations. Understanding the various types available helps in selecting the most appropriate option for specific needs.

Material-Based Food Tray Types

The material used in food trays significantly impacts their properties, including durability, temperature resistance, and environmental impact. Different materials cater to diverse requirements in the food industry.

- Plastic Food Trays: Plastic trays are widely used due to their versatility and cost-effectiveness. They are available in various forms, including:

- Polypropylene (PP): PP trays are microwave-safe and offer good resistance to chemicals and heat, making them suitable for hot foods.

- Polyethylene Terephthalate (PET): PET trays are commonly used for cold foods and deli items, providing clarity and a good barrier against moisture.

- Polystyrene (PS): PS trays are often used for packaging due to their rigidity and insulating properties. However, they are less environmentally friendly than some alternatives.

- Aluminum Food Trays: Aluminum trays excel in heat conductivity, making them ideal for baking and reheating food. They are also lightweight and recyclable.

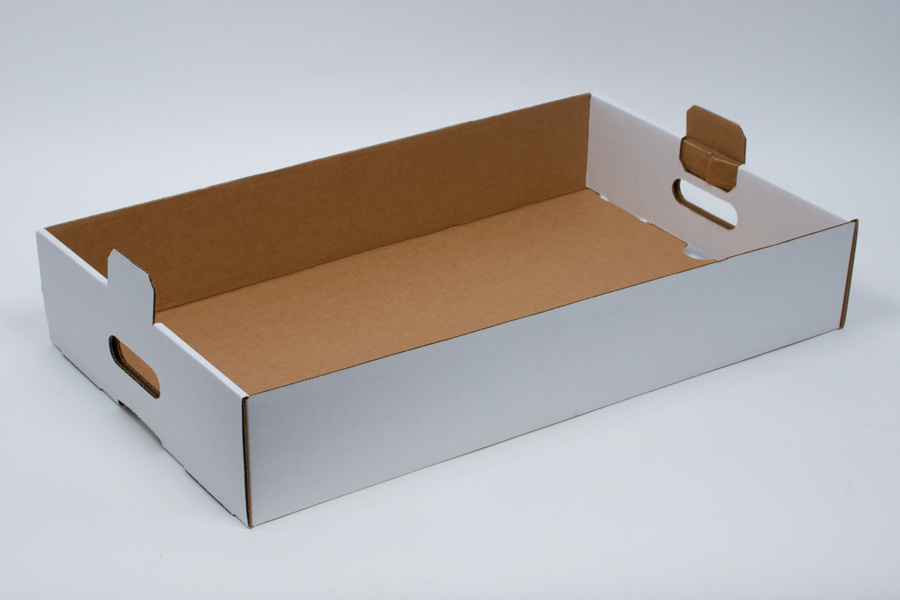

- Paper/Cardboard Food Trays: Paper and cardboard trays are a sustainable option, particularly when made from recycled materials. They are often used for sandwiches, salads, and other cold or dry items. They can be coated with a wax or a food-grade coating to provide moisture resistance.

- Foam Food Trays: Expanded polystyrene (EPS) foam trays offer excellent insulation, keeping food hot or cold for extended periods. However, they are not easily recyclable and have environmental concerns.

Disposable vs. Reusable Food Trays

The choice between disposable and reusable food trays depends on usage frequency, cost considerations, and environmental impact. Each type offers distinct advantages and disadvantages.

| Feature | Disposable Food Trays | Reusable Food Trays | Comparison | Examples |

|---|---|---|---|---|

| Cost | Generally lower upfront cost per unit. | Higher initial investment. | Disposable trays are often more affordable for single-use scenarios. Reusable trays become more cost-effective over time with repeated use. | Disposable: Plastic deli containers. Reusable: Restaurant-grade plastic trays. |

| Durability | Designed for single use; often less durable. | Made to withstand multiple uses; more durable. | Reusable trays are built to last and can withstand washing and handling over time. | Disposable: Foam takeout containers. Reusable: Heavy-duty plastic serving platters. |

| Environmental Impact | Can contribute to landfill waste if not recycled. | Reduces waste through multiple uses; often more sustainable. | Reusable trays have a lower environmental impact over their lifespan due to reduced waste. Proper cleaning and maintenance are crucial. | Disposable: Paper plates. Reusable: Stainless steel serving trays. |

| Convenience | Convenient for one-time use; no cleaning required. | Requires washing and storage. | Disposable trays offer ease of use, particularly for takeout or events. Reusable trays require more effort in terms of cleaning and storage. | Disposable: Aluminum foil pans. Reusable: Plastic food storage containers. |

Food Tray Designs Based on Food Type

Specific food trays with lids are designed to accommodate different food types, ensuring optimal preservation, presentation, and safety.

- Hot Food Trays: These trays are designed to maintain the temperature of hot foods.

- Materials: Often made from materials like PP plastic or aluminum, which can withstand high temperatures.

- Features: Lids typically have vents to release steam and prevent condensation. Insulation may be incorporated to retain heat.

- Examples: Takeout containers for soups, stews, and prepared meals.

- Cold Food Trays: These trays are designed to keep food chilled and fresh.

- Materials: Commonly made from PET plastic, which provides clarity and a good barrier against moisture.

- Features: Lids often seal tightly to prevent leaks and maintain freshness. Some trays include compartments to separate different food items.

- Examples: Salad containers, deli trays for sandwiches and cold cuts, and sushi trays.

- Deli Item Trays: Designed for presenting and protecting deli products.

- Materials: Typically made from clear or colored plastic to showcase the food.

- Features: Secure lids that provide a tight seal to preserve freshness and prevent spills. Often designed to be stackable for efficient display and storage.

- Examples: Trays for sliced meats, cheeses, and prepared salads.

Applications and Uses

Food trays with lids offer versatile solutions across various sectors, providing practical benefits for food handling, storage, and transportation. Their design addresses critical needs in maintaining food quality, safety, and presentation, making them indispensable tools in the modern food industry.

Industries Utilizing Food Trays with Lids

Several industries heavily rely on food trays with lids to streamline their operations and ensure food integrity. These industries benefit from the protection, organization, and efficiency that these trays provide.

- Restaurants: Restaurants use food trays with lids for various purposes, from storing prepped ingredients to packaging takeout orders.

- Catering Services: Catering companies employ these trays extensively for transporting and serving food at events, ensuring food stays fresh and organized.

- Food Delivery Services: Delivery services utilize these trays to package meals for delivery, maintaining food temperature and preventing spills during transit.

- Grocery Stores and Supermarkets: These retailers use food trays with lids for pre-packaged meals, deli items, and prepared foods, offering convenience to customers.

- Food Processing and Manufacturing: Food manufacturers use trays for portioning, storing, and transporting ingredients and finished products.

- Healthcare Facilities: Hospitals and nursing homes use food trays with lids to serve meals to patients, ensuring hygiene and ease of handling.

Applications in Restaurants, Catering, and Food Delivery

Food trays with lids play crucial roles in optimizing food handling practices within restaurants, catering businesses, and food delivery services. Their design contributes significantly to efficiency, safety, and customer satisfaction.

- Restaurants: Restaurants use food trays with lids to store ingredients in the kitchen, manage portion control, and package takeout and delivery orders. For example, a restaurant might use trays to pre-portion ingredients for a specific dish, reducing prep time and ensuring consistency. They also use trays to package meals for takeout, keeping the food secure and preventing spills.

- Catering Services: Catering companies utilize food trays with lids to transport prepared food to event locations, maintain food temperature, and present food elegantly. Catering companies frequently use insulated trays to keep hot foods hot and cold foods cold during transit. These trays also help organize the food for easy serving.

- Food Delivery Services: Delivery services rely on food trays with lids to package meals securely for transport, preserving food quality and preventing leakage. Many delivery services use insulated trays to maintain the food’s temperature during transit, ensuring that the customer receives the meal as intended. These trays are also designed to stack easily, optimizing space for delivery drivers.

Advantages of Food Trays with Lids for Food Storage and Transportation

Food trays with lids provide several significant advantages for food storage and transportation, enhancing food safety, extending shelf life, and improving operational efficiency. These benefits contribute to reduced waste and improved customer satisfaction.

- Enhanced Food Safety: Lids create a barrier against contamination, preventing exposure to airborne particles, pests, and other environmental hazards. This protection is crucial for maintaining food safety standards.

- Extended Shelf Life: By sealing food, lids help to preserve freshness and prevent spoilage. This is particularly important for perishable items, as it helps to extend their usable life.

- Temperature Control: Many food trays with lids are designed with insulation to maintain the desired temperature of the food. This is especially important for hot and cold foods, ensuring that they remain at the correct temperature during transport and storage.

- Preventing Spills and Leaks: Lids provide a secure seal, preventing spills and leaks during transportation. This is critical for maintaining hygiene and preventing messes, especially in food delivery services.

- Improved Organization: Food trays with lids help to organize food items, making it easier to manage inventory and portion control. This organization streamlines operations and reduces waste.

- Stackability and Space Efficiency: The design of food trays with lids often allows for stacking, maximizing storage space and making them ideal for transport and storage. This is particularly useful in catering and food delivery services.

Features and Benefits

Food trays with lids offer a multitude of features designed to enhance food preservation, convenience, and usability. These features translate into significant benefits for both consumers and businesses, streamlining operations and improving the overall food experience. Understanding these aspects is crucial when selecting the right food tray solution for specific needs.

Airtight and Leak-Proof Lid Importance

The integrity of a food tray’s lid is paramount for maintaining food quality and preventing messes. Airtight and leak-proof lids are essential for preserving food freshness, preventing contamination, and ensuring safe transport.

Airtight seals prevent oxygen from reaching the food, which can cause spoilage and degradation.

This is particularly important for perishable items like prepared meals, salads, and deli items. Leak-proof lids prevent spills and leaks, which are crucial for preventing cross-contamination, maintaining cleanliness, and ensuring the food arrives in optimal condition. They also minimize the risk of unpleasant odors escaping, which is important for both storage and transport. Consider the example of a restaurant offering takeout.

A leak-proof lid guarantees that the customer’s meal arrives intact and prevents sauces or liquids from spilling during transit.

Stacking and Microwavability Benefits

Stacking and microwavability are highly desirable features that add significant value to food trays with lids, contributing to space efficiency and convenience. These features cater to modern lifestyles and operational needs.

- Stacking: Stackable food trays maximize storage space, especially in refrigerators, freezers, and pantries. This is a considerable advantage for restaurants, caterers, and consumers who need to store multiple food items efficiently. For example, a restaurant using stackable trays can organize prepped ingredients and meals in a compact manner, optimizing kitchen space. The design allows for stable stacking without compromising the integrity of the food or the trays.

- Microwavability: Microwavable food trays offer unparalleled convenience for reheating meals. This feature allows consumers to enjoy prepared foods quickly and easily, without the need to transfer the food to another container. This is a critical feature for busy individuals and families. Consider the convenience of a pre-prepared meal that can be heated directly in its tray, saving time and reducing the need for washing additional dishes.

Many food trays are made from polypropylene (PP) plastic, a material known for its microwave-safe properties. Always verify the tray’s label for specific microwave instructions.

Lid Closure Mechanisms

The lid closure mechanism significantly impacts the ease of use, sealing effectiveness, and overall functionality of food trays. Different closure mechanisms cater to various needs and preferences.

- Snap-on Lids: Snap-on lids are a popular choice due to their ease of use and secure closure. They typically feature a lip that snaps onto the tray’s rim, creating a relatively airtight seal. This mechanism is suitable for a wide range of applications, from storing leftovers to packaging prepared meals. The ease of snapping the lid on and off makes them convenient for everyday use.

- Hinged Lids: Hinged lids are permanently attached to the tray, offering convenience and preventing the lid from getting lost. These are common in clamshell containers for sandwiches, salads, and other grab-and-go items. The hinged design allows for easy opening and closing, making them ideal for quick access to the food.

- Sealed Lids: Sealed lids, often found on food trays for ready-to-eat meals or deli items, provide the highest level of airtightness and leak-proof protection. These lids are typically sealed onto the tray using heat or pressure, creating a tamper-evident barrier. This mechanism ensures the food’s freshness and safety, and it is particularly crucial for products with a long shelf life or those requiring stringent hygiene standards.

Examples include pre-packaged salads or prepared meals in grocery stores.

Materials and Sustainability

The materials used to manufacture food trays with lids significantly impact their environmental footprint. Understanding these impacts, alongside the available recycling and composting options, is crucial for promoting sustainable practices within the food industry. Furthermore, implementing waste reduction strategies can minimize the overall environmental burden associated with these essential packaging items.

Environmental Impact of Different Food Tray Materials

The environmental impact of food trays with lids varies considerably depending on the material used in their construction. This impact is assessed through the entire lifecycle of the product, from raw material extraction and manufacturing to transportation, use, and disposal.

For descriptions on additional topics like food 4 less beaumont ca, please visit the available food 4 less beaumont ca.

- Polystyrene (PS): Polystyrene, often used in the form of expanded polystyrene (EPS) or Styrofoam, presents significant environmental challenges. Its production relies on petroleum, a non-renewable resource, and the manufacturing process can release harmful volatile organic compounds (VOCs). EPS is notoriously difficult to recycle due to its lightweight nature and bulkiness, leading to landfill accumulation and potential marine pollution. Furthermore, it can take hundreds of years to decompose.

- Polypropylene (PP): Polypropylene is another common plastic used for food trays. While also derived from petroleum, PP is generally considered a more environmentally favorable option than PS. It is more readily recyclable than PS in many regions and is resistant to many chemicals, which makes it a better choice for a wide variety of foods. However, like all plastics, its production and disposal still contribute to greenhouse gas emissions and plastic pollution.

- Polyethylene Terephthalate (PET): PET is a widely recycled plastic, often used for clear food trays and lids. Its recyclability is a key advantage, as it can be processed into new products, reducing the demand for virgin plastic. PET manufacturing still consumes energy and resources, and contamination with other plastics can hinder its recyclability.

- Paperboard: Paperboard trays, often coated with a thin layer of plastic or wax for moisture resistance, offer a more sustainable alternative. They are made from renewable resources, and the paper itself is biodegradable and compostable. However, the manufacturing process can be energy-intensive, and the coatings can compromise their recyclability and compostability.

- Aluminum: Aluminum trays are recyclable indefinitely, making them a highly sustainable option. The recycling process requires significantly less energy than producing aluminum from bauxite ore. However, aluminum production is energy-intensive, and the mining of bauxite can have negative environmental impacts.

- Plant-Based Plastics (e.g., PLA): Polylactic acid (PLA) is a bioplastic derived from renewable resources like corn starch or sugarcane. PLA trays are often marketed as compostable, offering a biodegradable alternative to traditional plastics. However, PLA requires specific composting conditions (industrial composting facilities) to break down effectively, and they are not suitable for home composting. If PLA ends up in landfills, it will not biodegrade and could potentially contaminate traditional recycling streams.

Recycling and Composting Options for Various Food Tray Materials

The availability of recycling and composting options for food trays with lids varies depending on the material and the local infrastructure. Clear understanding of these options is critical for proper waste management.

- Polystyrene (PS): Recycling options for PS are limited. Few municipalities have the infrastructure to recycle PS due to its low density and potential contamination. Specialized drop-off locations or recycling programs may accept PS.

- Polypropylene (PP): PP is widely accepted in curbside recycling programs. Trays should be clean and free of food residue to ensure proper recycling.

- Polyethylene Terephthalate (PET): PET is also widely accepted in curbside recycling programs. Like PP, the trays should be clean and free of food residue.

- Paperboard: Paperboard trays are generally recyclable if they are clean and free of significant food contamination or plastic/wax coatings. The presence of these coatings can hinder the recycling process.

- Aluminum: Aluminum trays are readily recyclable through curbside recycling programs. Cleaning the trays before recycling is recommended.

- Plant-Based Plastics (e.g., PLA): PLA trays are typically compostable in industrial composting facilities. They are not designed for home composting. Checking local guidelines to determine if such facilities are available is essential.

Strategies for Reducing Waste Associated with Food Trays with Lids

Minimizing waste associated with food trays with lids requires a multi-pronged approach. This involves reducing the amount of packaging used, promoting reuse, and optimizing recycling and composting efforts.

- Reduce Packaging: Reducing the amount of packaging used is a fundamental strategy. This can involve using thinner materials, optimizing tray sizes to fit the food items, and exploring alternative packaging designs that require less material.

- Reusable Trays: Encouraging the use of reusable food trays, particularly in food service establishments, can significantly reduce waste. This could involve offering incentives for customers who bring their own containers or implementing a tray-return system.

- Optimize Recycling Programs: Enhancing recycling programs by providing clear instructions and promoting proper sorting can increase recycling rates. This includes educating consumers about the types of materials that can be recycled and how to prepare them for recycling.

- Promote Composting: Expanding access to industrial composting facilities and educating consumers about composting options can divert food trays made from compostable materials from landfills.

- Material Selection: Choosing food tray materials with a lower environmental impact is a crucial element. Prioritizing recyclable or compostable materials over non-recyclable plastics is a key decision.

- Design for Recyclability: Designing food trays with recyclability in mind is essential. This involves using materials that are easily separated and processed in recycling facilities and avoiding the use of mixed materials that can complicate the recycling process.

- Extended Producer Responsibility (EPR): Implementing EPR programs, where producers are responsible for the end-of-life management of their products, can incentivize the use of sustainable materials and promote waste reduction.

Manufacturing Processes

The production of food trays with lids involves diverse manufacturing techniques, depending on the materials used. Each process is tailored to optimize the properties of the chosen material, ensuring both functionality and cost-effectiveness. This section Artikels the key manufacturing processes for plastic, aluminum, and paper-based food trays with lids.

Manufacturing Plastic Food Trays with Lids

Plastic food trays with lids are typically manufactured using various methods, including injection molding, thermoforming, and extrusion. These processes are chosen based on the desired shape, size, and material properties of the tray and lid.* Injection Molding: This method is frequently used for creating complex shapes and intricate designs. Molten plastic is injected into a mold, where it cools and solidifies, taking the shape of the mold.

The resulting products have excellent dimensional accuracy and are suitable for mass production.

Thermoforming

This process involves heating a plastic sheet and then shaping it over a mold using vacuum or pressure. Thermoforming is ideal for creating trays with varying depths and designs. It is often more cost-effective for larger trays or lower production volumes compared to injection molding.

Extrusion

Extrusion is used to produce long, continuous plastic profiles. The plastic material is melted and forced through a die, which gives the final product its shape. Extruded trays can then be cut and assembled, or further processed to create lids.

Manufacturing Aluminum Food Trays with Lids

Aluminum food trays with lids are generally manufactured through a process called stamping or deep drawing. This process involves shaping aluminum sheets into the desired form using specialized machinery.* Stamping/Deep Drawing: Aluminum coils are fed into a stamping machine, where a die presses the metal into the desired tray shape. The process may involve multiple stages of drawing to achieve the required depth and form.

The lid is often formed in a separate stamping process.

Surface Treatment

After forming, the aluminum trays may undergo surface treatments, such as anodizing or coating, to improve corrosion resistance and provide a barrier for food contact. Anodizing creates a protective oxide layer on the surface, while coatings can provide additional protection and aesthetic appeal.

Assembly

The lid and tray are assembled, typically with a crimping or sealing process, to ensure a secure fit and prevent leakage.

Manufacturing Paper-Based Food Trays with Lids

Paper-based food trays with lids are often manufactured from materials like paperboard or molded pulp. The process involves several steps, designed to provide structural integrity and ensure food safety.* Pulp Preparation: For molded pulp trays, the process begins with the preparation of the pulp. This involves mixing paper fibers with water and additives to create a slurry. The type of fiber and additives can vary depending on the desired characteristics of the tray, such as strength and water resistance.

Molding

The pulp slurry is then molded into the desired shape using a mold. The water is removed, and the fibers interlock, forming the tray. This can be done through various molding techniques, including vacuum forming.

Drying and Finishing

After molding, the trays are dried to remove excess moisture. This process is critical for ensuring structural integrity. Finishing steps may include trimming, coating, or printing. Coatings can be applied to improve water resistance, grease resistance, and provide a barrier to prevent the food from sticking to the tray.

Lid Production

Lids are made from paperboard and cut to shape, often using die-cutting. The lids may be laminated with a plastic film or coated to enhance their barrier properties and provide a secure fit.

Design and Aesthetics: Food Trays With Lids

The visual appeal and functional design of food trays with lids are crucial elements that influence consumer perception, brand recognition, and the overall dining experience. Considerations extend beyond mere containment, encompassing ergonomics, branding opportunities, and the psychological impact of color and transparency. The design process necessitates a holistic approach, balancing practicality with aesthetic considerations to create packaging that resonates with consumers.

Ergonomics and Visual Appeal

Ergonomic design ensures that food trays with lids are easy to handle, stack, and transport, enhancing convenience for both consumers and food service providers. Visual appeal, on the other hand, aims to make the food more enticing, contributing to a positive dining experience.

- Shape and Form: The shape of a food tray can influence its functionality and visual appeal. Rectangular trays are often preferred for efficient space utilization and stacking, while oval or circular designs may be chosen for aesthetic reasons or to complement the food presentation. The form should also consider the food type; for example, a tray designed for sandwiches might have a lower profile than one for a layered salad.

- Ease of Use: Features like secure closures, easy-to-open lids, and comfortable grip areas enhance usability. Lids that snap securely into place prevent spills, while tabs or handles facilitate opening and closing.

- Stackability: Trays designed for stacking optimize storage space, particularly in busy kitchens or during transport. Features like recessed lids or interlocking bases contribute to stable stacking.

- Transparency: Clear lids provide a direct view of the food, increasing its visual appeal and allowing consumers to assess the contents without opening the tray. This is especially effective for showcasing colorful salads, desserts, or visually appealing entrees.

- Surface Finish: The surface finish can affect both the aesthetics and the tactile experience. A glossy finish can enhance the vibrancy of colors, while a matte finish might convey a sense of premium quality or a more natural aesthetic. The finish should also be chosen to resist scratching and staining.

Branding and Labeling Integration

Food trays with lids offer valuable real estate for branding and labeling, enabling businesses to enhance brand recognition and provide essential product information.

- Logo Placement: The placement of a company logo can significantly impact brand visibility. Logos can be embossed, printed, or incorporated into the lid’s design. The logo should be clearly visible, even when the tray is stacked or displayed in a retail setting.

- Color Palette: The color palette of the tray and lid can be aligned with the brand’s identity. Consistent use of brand colors across packaging reinforces brand recognition and creates a cohesive visual experience.

- Label Design: Labels provide crucial information about the product, including ingredients, nutritional facts, and preparation instructions. Label design should be clear, legible, and compliant with food safety regulations. The placement of the label should not obstruct the view of the food.

- Customization: Food tray designs can be customized to reflect a specific brand aesthetic or promotional campaign. This includes incorporating unique shapes, textures, or graphic elements that differentiate the product from competitors.

- QR Codes: QR codes can be printed on the tray or lid to provide consumers with additional information, such as recipes, promotions, or links to the company website.

Color and Transparency Impact

The color and transparency of food trays with lids have a profound impact on consumer perception and purchasing decisions. These elements influence how consumers perceive the freshness, quality, and appeal of the food inside.

- Color Psychology: Different colors evoke different emotions and associations. For example, red and yellow are often used to stimulate appetite, while green can convey freshness and natural ingredients. The choice of color should align with the type of food and the desired brand message.

- Transparency’s Influence: Transparent lids allow consumers to see the food directly, which often increases the perceived freshness and appeal. This is especially effective for showcasing colorful salads, desserts, or visually appealing entrees. Clear lids also build trust by allowing consumers to verify the contents before purchase.

- Opaque Trays: Opaque trays are often used to protect food from light exposure or to conceal less visually appealing items. These trays may be preferred for hot foods, as they can help to maintain temperature and prevent condensation.

- Tinted Trays: Tinted trays can be used to create a specific aesthetic or to filter light. For example, a slightly tinted lid might enhance the colors of the food while still allowing for visibility.

- Examples: Consider the impact of color in fast-food packaging. McDonald’s uses red and yellow, colors that are known to stimulate appetite, while many health food brands use green and earth tones to communicate freshness and natural ingredients.

Regulations and Standards

Food trays with lids are subject to a complex web of regulations and standards designed to ensure food safety and protect consumer health. Compliance with these guidelines is critical for manufacturers and distributors to legally market their products and maintain consumer trust. These regulations cover various aspects, including the materials used, manufacturing processes, and labeling requirements.

Relevant Food Safety Regulations

Several key food safety regulations directly impact the production and use of food trays with lids. These regulations vary by country and region, but generally address similar concerns related to food contamination and consumer safety.

- Food and Drug Administration (FDA) in the United States: The FDA sets regulations for food contact materials under the Federal Food, Drug, and Cosmetic Act (FFDCA). The FDA ensures that food trays with lids are safe for their intended use and do not pose a risk of contamination or harm to consumers. This involves reviewing the materials used in the trays and ensuring they meet specific migration limits, meaning that chemicals from the tray cannot leach into the food at levels that could be harmful.

- European Food Safety Authority (EFSA) in Europe: EFSA provides scientific advice and risk assessments on food safety matters, including food contact materials. The framework regulation (EC) No 1935/2004 establishes the general principles for all food contact materials. This regulation requires that food contact materials, including trays and lids, are manufactured in compliance with Good Manufacturing Practice (GMP) to ensure they do not transfer substances to food in quantities that could endanger human health or change the composition, taste, or odor of the food.

- Canadian Food Inspection Agency (CFIA) in Canada: The CFIA enforces food safety regulations, including those related to food contact materials. Similar to the FDA and EFSA, the CFIA ensures that food trays and lids are safe and do not pose a risk to consumer health. They often align with international standards, like those from the FDA and EFSA, or create their own based on specific Canadian needs and concerns.

- Specific Regulations for Different Materials: Regulations may also be specific to the type of material used in the food tray. For example, regulations for plastics, such as polyethylene (PE) and polypropylene (PP), often address the types of additives that can be used and the permitted levels of migration into food. Similarly, regulations for paper and paperboard focus on the use of inks, coatings, and other additives.

Certifications and Standards for Food Tray Materials

Certifications and standards play a vital role in ensuring the safety and quality of food tray materials. These certifications provide assurance to manufacturers, retailers, and consumers that the materials meet specific requirements.

- FDA Compliance: Food trays with lids sold in the United States must comply with FDA regulations. Manufacturers typically provide documentation demonstrating that their materials meet FDA requirements. This documentation may include a “Letter of No Objection” or a “Food Contact Notification” (FCN) for specific materials or formulations.

- EU Compliance: In Europe, food tray materials must comply with the framework regulation (EC) No 1935/2004 and specific material regulations. Manufacturers often obtain declarations of compliance (DoC) from their suppliers, indicating that the materials meet the relevant EU regulations.

- ISO Standards: The International Organization for Standardization (ISO) develops and publishes a wide range of international standards. While there isn’t a specific ISO standard solely for food trays, relevant standards, such as those for quality management (ISO 9001) and environmental management (ISO 14001), can be applied to the manufacturing process.

- BPA-Free Certification: Many food trays are marketed as “BPA-free” (Bisphenol A-free). This certification indicates that the tray does not contain BPA, a chemical that has raised health concerns. Manufacturers often obtain third-party certifications to verify the absence of BPA.

- Recycling Certifications: With increasing focus on sustainability, recycling certifications are becoming more important. Certifications such as those from the Sustainable Forestry Initiative (SFI) or the Forest Stewardship Council (FSC) can be used for paper-based trays to indicate that the materials are sourced from sustainably managed forests. Other certifications can be applied to plastic trays to indicate their recyclability.

Regulations for Food Contact Materials

Regulations for food contact materials are designed to prevent the migration of harmful substances from the tray or lid into the food. These regulations cover a wide range of aspects, including the types of materials that can be used, the permissible levels of certain substances, and the testing methods that must be employed.

- Migration Limits: A key aspect of food contact material regulations is setting migration limits. These limits specify the maximum amount of a substance that can migrate from the tray or lid into the food under specific conditions of use. Migration limits are often expressed in milligrams of substance per kilogram of food (mg/kg). The FDA, EFSA, and other regulatory bodies set migration limits for various substances, including monomers, additives, and contaminants.

- Good Manufacturing Practice (GMP): GMP guidelines are essential for ensuring the safety and quality of food contact materials. GMP covers all aspects of the manufacturing process, from the selection of raw materials to the final packaging of the product. This includes proper cleaning, sanitation, and process controls to prevent contamination.

- Testing and Analysis: Manufacturers of food trays with lids must conduct testing and analysis to demonstrate compliance with food contact material regulations. This testing often involves simulating the conditions of use, such as the temperature, contact time, and type of food, and then measuring the migration of substances from the tray into the food simulant. The results of these tests are used to determine whether the tray meets the applicable migration limits.

- Material Declarations: Manufacturers are often required to provide material declarations, which list the substances used in the production of the food tray. These declarations help regulatory agencies and food manufacturers assess the safety of the food tray.

- Labeling Requirements: Food trays with lids must comply with labeling requirements. Labels must provide information about the materials used in the tray, the intended use, and any necessary warnings or instructions.

Cost Analysis

Understanding the cost dynamics of food trays with lids is crucial for businesses aiming to optimize their packaging expenses. The pricing of these essential items is influenced by a variety of factors, and a comprehensive cost analysis allows for informed decision-making, balancing functionality, sustainability, and budgetary constraints. Evaluating the total cost of ownership, which includes initial purchase, storage, and disposal or cleaning, is vital for a complete financial assessment.

Cost Comparison of Food Tray Materials and Designs

The material and design choices significantly impact the cost of food trays. Each material offers a different balance between price, performance, and environmental impact. Furthermore, the design complexity can influence manufacturing costs, affecting the final price.

- Plastic Trays: Plastic trays, particularly those made from polypropylene (PP) or polyethylene terephthalate (PET), often represent a cost-effective option, especially in high volumes. Their low material cost and efficient manufacturing processes contribute to their affordability. However, the environmental impact of certain plastics, coupled with fluctuating oil prices (a primary raw material), can affect long-term cost stability.

- Paperboard Trays: Paperboard trays, often made from recycled materials, can be competitive in terms of cost, especially when considering the increasing demand for sustainable options. The cost can vary depending on the paperboard type, coating, and printing requirements. Design complexity, such as intricate folding or custom shapes, can increase manufacturing costs.

- Foam Trays: Expanded polystyrene (EPS) or foam trays offer a low-cost solution for insulation and cushioning. However, environmental concerns surrounding their recyclability and disposal often lead to increased disposal costs and regulatory scrutiny, which can indirectly impact the overall cost-effectiveness.

- Aluminum Trays: Aluminum trays are generally more expensive than plastic or paperboard due to the higher material costs and energy-intensive manufacturing processes. However, their superior heat conductivity, durability, and recyclability can justify the investment for specific applications, particularly in the food service industry.

- Design Complexity: The complexity of the tray design influences manufacturing costs. Simple designs with minimal features are typically less expensive to produce than those with intricate shapes, multiple compartments, or custom closures. For instance, a single-compartment rectangular tray is less costly than a tray with several dividers and a snap-on lid.

Factors Influencing the Pricing of Food Trays with Lids

Several factors collectively determine the final price of food trays with lids. These include material costs, manufacturing processes, design specifications, order volume, and geographic location.

- Material Costs: The cost of raw materials is a primary driver of pricing. Fluctuations in the prices of petroleum-based plastics, wood pulp for paperboard, or aluminum can significantly impact the final product cost.

- Manufacturing Processes: The efficiency and complexity of the manufacturing process play a crucial role. Injection molding for plastics, die-cutting for paperboard, and stamping for aluminum all have associated costs, including labor, energy, and equipment maintenance. Automation and economies of scale can reduce per-unit costs.

- Design Specifications: Custom designs, including unique shapes, sizes, and features, generally command a higher price than standard, off-the-shelf options. The complexity of the design influences mold or tooling costs, as well as the manufacturing process.

- Order Volume: Bulk orders typically result in lower per-unit costs due to economies of scale. Manufacturers can often offer significant discounts for larger quantities, as it reduces setup and handling costs per tray.

- Geographic Location: Transportation costs, labor rates, and local regulations vary by geographic location, affecting the final price. Sourcing trays from a manufacturer closer to the end-user can reduce shipping expenses.

- Lid Type: The type of lid used significantly impacts the overall cost. Snap-on lids, hinged lids, and heat-sealable films all have different material and manufacturing costs. The design and material of the lid directly influence the tray’s functionality and price.

Cost Breakdown of Disposable Versus Reusable Food Trays

The choice between disposable and reusable food trays involves a trade-off between initial cost, long-term expenses, and environmental impact. A comprehensive cost breakdown considers all aspects, including purchase price, cleaning, storage, and disposal.

| Cost Factor | Disposable Food Trays | Reusable Food Trays | Notes/Examples |

|---|---|---|---|

| Initial Purchase Cost | Generally lower per unit, especially in bulk. | Higher initial investment due to durable materials and more complex manufacturing. | Example: Disposable plastic tray costs $0.10 per unit; Reusable polycarbonate tray costs $2.00 per unit. |

| Cleaning and Maintenance | No cleaning required. | Requires washing, sanitizing, and potential repairs or replacements. | Example: Commercial dishwasher operation, labor costs for cleaning. |

| Storage Costs | Minimal storage space needed. | Requires significant storage space, especially for large quantities. | Example: Warehouse space, shelving, and inventory management costs. |

| Disposal Costs | Disposal fees, waste management costs. | Potentially lower disposal costs (if recycled) or none (if reused indefinitely). | Example: Landfill fees, recycling program costs. |

| Environmental Impact | Higher environmental impact due to resource consumption and waste generation. | Lower environmental impact if used for an extended period and properly recycled at the end of its life. | Example: Carbon footprint analysis, waste reduction initiatives. |

Innovations and Trends

The food tray industry is continuously evolving, driven by consumer demand, technological advancements, and a growing emphasis on sustainability. This section explores the cutting-edge developments shaping the future of food trays with lids, highlighting emerging trends and innovative solutions.

Emerging Trends in Food Tray Design and Functionality

Several trends are reshaping the landscape of food tray design and functionality, impacting both consumer experience and operational efficiency. These advancements are driven by the need for improved convenience, enhanced food preservation, and reduced environmental impact.

- Smart Packaging Integration: The integration of smart technologies, such as QR codes, NFC tags, and sensors, is becoming increasingly prevalent. These technologies provide consumers with access to product information, traceability data, and interactive content, enhancing the overall user experience. For example, a QR code on a food tray could link to recipe suggestions or nutritional information, adding value beyond mere food containment.

- Enhanced Convenience Features: Food trays are incorporating features designed to improve convenience, such as resealable lids, portion control compartments, and microwave-safe designs. These features cater to the fast-paced lifestyles of modern consumers. The incorporation of features like built-in utensils or compartments for sauces and condiments are also gaining popularity.

- Improved Food Preservation Technologies: Innovations in food preservation are being integrated into tray design. Modified atmosphere packaging (MAP) and active packaging technologies extend shelf life and maintain food quality. For example, trays with oxygen-absorbing films can significantly reduce spoilage, especially for fresh produce and ready-to-eat meals.

- Customization and Personalization: There is a growing demand for customized food tray designs to meet specific product requirements and brand identities. This includes options for unique shapes, sizes, and printing capabilities, allowing companies to differentiate their products on the shelf. Customized tray designs are especially useful for meal-kit companies or those offering subscription services.

- Modular and Reusable Systems: The rise of modular and reusable food tray systems reflects a shift towards sustainability. These systems often involve trays designed to be used multiple times, reducing waste and promoting circular economy models. These trays can be returned to the supplier or manufacturer for cleaning and reuse.

Innovations in Sustainable Materials for Food Trays with Lids

Sustainability is a major driver of innovation in the food tray industry. The development of eco-friendly materials is critical for reducing the environmental impact of food packaging.

- Bio-based Plastics: The use of bio-based plastics derived from renewable resources, such as cornstarch, sugarcane, and cellulose, is increasing. These materials offer a lower carbon footprint compared to traditional petroleum-based plastics. Polylactic acid (PLA), a common bio-based plastic, is biodegradable under specific composting conditions.

- Compostable Materials: Compostable food trays are designed to break down into natural components in a composting environment. Materials like paperboard, molded pulp, and certain types of bio-plastics are commonly used. The success of compostable trays depends on access to composting facilities and proper disposal methods.

- Recycled and Recyclable Materials: The use of recycled materials, such as recycled PET (rPET) and recycled paper, is becoming more prevalent. These materials reduce the demand for virgin resources and contribute to a circular economy. Ensuring the recyclability of trays is also a key focus, with designs that minimize the use of mixed materials.

- Mushroom Packaging and Other Innovative Materials: Innovative materials like mushroom packaging (Mycelium) are emerging as alternatives. Mushroom packaging is created by growing mycelium (the root structure of mushrooms) around agricultural waste. These materials are compostable and offer excellent cushioning properties. Other innovative materials include seaweed-based packaging and biodegradable films.

- Plant-Based Coatings and Inks: The use of plant-based coatings and inks on food trays is gaining traction, reducing the reliance on petroleum-based alternatives. These coatings and inks can enhance the functionality and aesthetics of the trays while minimizing environmental impact. For example, soy-based inks are a popular alternative to traditional petroleum-based inks.

Potential Future Developments in the Food Tray Industry

The food tray industry is poised for significant advancements in the coming years, driven by ongoing research, technological breakthroughs, and evolving consumer preferences.

- Active and Intelligent Packaging: The development of active and intelligent packaging is expected to accelerate. This includes trays that can monitor food freshness, release preservatives, or change color to indicate spoilage. Sensors embedded in the tray could track temperature, humidity, and other factors affecting food quality.

- 3D-Printed Food Trays: 3D printing technology could revolutionize food tray manufacturing, enabling customized designs, rapid prototyping, and on-demand production. This could lead to greater flexibility and reduced waste.

- Edible Food Trays: Research is underway on developing edible food trays made from ingredients like seaweed or rice flour. These trays would eliminate packaging waste entirely.

- Advanced Barrier Technologies: The development of advanced barrier technologies will improve food preservation and extend shelf life. This includes the use of nanotechnology and thin films to create highly effective barriers against oxygen, moisture, and other contaminants.

- Increased Focus on Traceability and Transparency: Blockchain technology and other traceability solutions will enhance supply chain transparency, allowing consumers to track the origin and journey of their food. This is particularly important for ensuring food safety and sustainability.

Purchasing and Sourcing

Selecting and sourcing food trays with lids is a critical process that significantly impacts operational efficiency, cost-effectiveness, and ultimately, the quality of food service. Careful consideration of various factors ensures that the chosen trays meet specific needs and align with the overall business strategy. This section will guide you through the essential aspects of purchasing and sourcing food trays with lids.

Factors for Selecting Food Trays with Lids

The selection of food trays with lids requires a detailed evaluation of several key factors to ensure they meet the specific requirements of their intended use. These factors influence functionality, cost, and overall suitability.

- Food Type and Temperature: Consider the type of food being served and the temperature range it will encounter. Trays for hot foods require heat-resistant materials, while those for cold foods should maintain appropriate temperatures. For instance, polypropylene (PP) trays are suitable for a wide range of temperatures, while expanded polystyrene (EPS) trays are better for insulation.

- Durability and Handling: Evaluate the durability of the trays based on the intended handling and transportation methods. Trays that will be frequently handled or transported long distances should be more robust. Impact resistance and stacking capabilities are important considerations. For example, restaurants with high turnover may require more durable trays than catering services that deliver food less frequently.

- Size and Capacity: Determine the appropriate size and capacity of the trays based on portion sizes and meal configurations. Consider the need for single-compartment or multi-compartment trays to accommodate different food items. Different sizes are needed for a variety of purposes, such as single-serving meals versus family-sized portions.

- Lid Compatibility and Seal: Ensure the lids fit securely and provide an effective seal to prevent spills and maintain food freshness. The lid material should also be compatible with the tray material and food type. For example, snap-on lids offer a secure seal for transport, while vented lids are suitable for hot foods.

- Material and Environmental Impact: Assess the material of the trays, considering factors such as recyclability, compostability, and the overall environmental impact. Sustainable options, such as trays made from recycled materials or biodegradable plastics, are increasingly preferred. For example, some companies are shifting from conventional plastics to plant-based materials.

- Cost and Budget: Analyze the cost of the trays, including the initial purchase price, potential shipping costs, and any ongoing maintenance expenses. Consider the total cost of ownership, including factors such as durability and longevity. Bulk purchasing often reduces per-unit costs.

- Regulatory Compliance: Ensure the trays comply with relevant food safety regulations and standards, such as those set by the FDA or other local authorities. This includes materials that are safe for food contact and are free from harmful chemicals.

Guide to Sourcing Food Trays with Lids

Sourcing food trays with lids involves identifying and evaluating potential suppliers. A systematic approach is important to ensure a reliable and cost-effective supply chain.

- Identify Potential Suppliers: Research and identify potential suppliers through online directories, industry trade shows, and referrals. Consider both domestic and international suppliers to compare pricing and capabilities.

- Request Samples and Quotes: Request samples of trays from multiple suppliers to evaluate their quality, durability, and suitability for your specific needs. Obtain detailed quotes, including pricing, minimum order quantities (MOQs), lead times, and shipping costs.

- Evaluate Supplier Capabilities: Assess the supplier’s manufacturing capabilities, quality control processes, and ability to meet your volume and customization requirements. Consider their experience in the food service industry.

- Negotiate Terms and Conditions: Negotiate favorable terms and conditions, including pricing, payment terms, and warranty policies. Establish clear expectations regarding product quality, delivery schedules, and returns.

- Conduct Due Diligence: Conduct due diligence on potential suppliers, including checking their financial stability, certifications, and references. Verify their compliance with relevant regulations and standards.

- Establish a Long-Term Relationship: Once a reliable supplier is identified, establish a long-term relationship to ensure a consistent supply of high-quality trays and lids. This can include regular communication, performance reviews, and collaborative efforts to improve product quality and efficiency.

Lead Times and Minimum Order Quantities

Lead times and minimum order quantities (MOQs) are crucial factors that significantly influence the purchasing process. They directly affect inventory management, storage costs, and the ability to meet customer demands.

- Understanding Lead Times: Lead times represent the time between placing an order and receiving the goods. They can vary significantly depending on the supplier, the complexity of the product, and the manufacturing process. Long lead times require careful planning to ensure sufficient inventory.

- Impact of Lead Times: Long lead times can lead to increased inventory costs, the need for larger storage space, and the risk of stockouts if demand fluctuates. Conversely, shorter lead times offer greater flexibility and responsiveness to changing market conditions.

- Negotiating Lead Times: Discuss lead times with suppliers and explore options to shorten them, such as prioritizing your order or using expedited shipping methods. Consider establishing a blanket purchase order to secure production capacity.

- Minimum Order Quantities (MOQs): MOQs represent the minimum number of units that a supplier requires for an order. MOQs can vary significantly depending on the supplier, the product, and the level of customization.

- Impact of MOQs: High MOQs can lead to excessive inventory, increased storage costs, and the risk of obsolescence. Low MOQs offer greater flexibility but may result in higher per-unit costs.

- Balancing MOQs and Demand: Carefully analyze your demand patterns and storage capacity to determine the optimal MOQ. Consider purchasing trays in phases to avoid overstocking and minimize waste.

- Example Scenario: A fast-food chain anticipates a promotion that will require 50,000 food trays with lids. A supplier offers a lead time of 6 weeks and an MOQ of 25,000 units. The chain must weigh the lead time against the potential storage costs and risk associated with a second order.

Maintenance and Care

Proper maintenance and care are crucial for extending the lifespan and ensuring the safe use of food trays with lids, especially for reusable options. Regular cleaning, careful storage, and mindful handling are key to preventing damage and maintaining hygiene standards. This section details best practices for maintaining these essential food service items.

Cleaning Reusable Food Trays with Lids

Effective cleaning is paramount for maintaining hygiene and the integrity of reusable food trays and lids. This involves removing food residue, sanitizing surfaces, and ensuring thorough drying to prevent bacterial growth.

- Pre-Cleaning: Immediately after use, remove any food scraps or debris. Rinse the trays and lids with warm water to loosen any remaining food particles. For trays with stubborn food residue, a pre-soak in warm, soapy water can be beneficial.

- Washing: Wash the trays and lids using a suitable detergent and warm water. A commercial dishwasher is often the most effective method, ensuring high-temperature sanitation. If washing by hand, use a sponge or soft brush to scrub all surfaces, paying particular attention to corners and crevices.

- Rinsing: Rinse thoroughly with clean, hot water to remove all traces of detergent. Residual detergent can leave a soapy taste and affect the cleanliness of the trays.

- Sanitizing: After washing and rinsing, sanitize the trays and lids to kill any remaining bacteria. Use a food-safe sanitizer, following the manufacturer’s instructions for concentration and contact time. Common sanitizing agents include chlorine-based solutions, quaternary ammonium compounds, and heat.

- Drying: Allow the trays and lids to air dry completely or use a clean, dry towel. Ensure they are completely dry before storage to prevent mold and mildew growth.

- Inspection: Regularly inspect the trays and lids for any signs of damage, such as cracks, chips, or discoloration. Discard any trays or lids that are compromised, as they may harbor bacteria or pose a safety hazard.

Storing Food Trays with Lids

Proper storage is essential for maintaining the condition and longevity of food trays with lids. This involves protecting them from damage, ensuring they remain clean, and optimizing storage space.

- Cleanliness: Always store trays and lids after they have been thoroughly cleaned and dried. This prevents the growth of mold, mildew, and bacteria.

- Stacking: Stack trays and lids neatly to conserve space. Consider using racks or shelving units specifically designed for food service items. If stacking trays, ensure they are stacked correctly to prevent damage.

- Lid Storage: Store lids separately from the trays, ideally in a designated area. This prevents them from being scratched or damaged.

- Protection from Elements: Store trays and lids in a dry, well-ventilated area away from direct sunlight and extreme temperatures. Exposure to these elements can degrade the materials and shorten their lifespan.

- Preventing Cross-Contamination: Store trays and lids away from chemicals, cleaning supplies, and other potential contaminants. This helps to prevent the transfer of odors and flavors to the food.

- Inventory Management: Implement an inventory management system to track the number of trays and lids in use and storage. This helps to ensure that there are always enough trays and lids available and that replacements can be ordered when needed.

Preventing Damage During Use and Storage

Taking proactive measures to prevent damage to food trays with lids is crucial for their longevity and the safety of the food they contain. Careful handling and proper storage practices minimize the risk of cracks, chips, and other forms of damage.

- Careful Handling: Handle trays and lids with care during use and transportation. Avoid dropping them or subjecting them to excessive force.

- Temperature Control: Avoid extreme temperature changes, as these can cause the materials to warp or crack. Do not place hot trays directly onto cold surfaces, or vice versa.

- Avoiding Sharp Objects: Avoid using sharp objects, such as knives or forks, directly on the trays. This can scratch the surface and compromise the integrity of the material. Use cutting boards when preparing food directly in the trays.

- Secure Lids: Ensure lids are securely fastened during transport to prevent spills and contamination.

- Proper Loading: Avoid overloading trays, as this can cause them to warp or break. Distribute the weight evenly to prevent stress on any one part of the tray.

- Regular Inspection: Regularly inspect trays and lids for any signs of damage, such as cracks, chips, or discoloration. Address any damage promptly to prevent further deterioration.

- Protective Measures: Consider using protective measures, such as tray liners or dividers, to prevent food from sticking to the tray and to facilitate cleaning.

Safety and Handling

The safe handling of food trays with lids is paramount to prevent injury and maintain food integrity. Proper procedures encompass safe handling of both the trays and the food they contain, as well as responsible disposal practices. This section Artikels crucial safety guidelines for various aspects of food tray usage.

Safe Handling of Food Trays with Lids

Proper handling techniques are essential to prevent burns, spills, and cross-contamination. This involves awareness of the food’s temperature and the tray’s material properties.

- Handling Hot Foods: When handling food trays containing hot food, always use appropriate protective equipment. This includes insulated gloves or oven mitts to prevent burns. Avoid carrying trays excessively full to minimize the risk of spills. Consider the weight distribution to maintain balance.

- Tray Material Awareness: Be mindful of the material the tray is made of. Some materials, like certain plastics, can become soft or deform when exposed to high temperatures. Others, like metal trays, can become extremely hot. Always check the manufacturer’s specifications for temperature limits and handling recommendations.

- Lid Security: Ensure lids are securely fastened before transporting or moving the trays. This prevents spills and maintains food temperature. If the lid doesn’t fit properly, do not use the tray.

- Ergonomics: When lifting or carrying food trays, use proper lifting techniques. Bend at the knees, keep your back straight, and hold the tray close to your body to reduce strain. Distribute the weight evenly if carrying multiple trays.

- Cleanliness: Always handle food trays with clean hands and use clean surfaces. Avoid cross-contamination by keeping raw and cooked foods separate, and by cleaning trays thoroughly before reuse.

Proper Disposal Methods

The correct disposal of food trays with lids is crucial for environmental protection and public health. Disposal methods vary based on the tray material and local regulations.

- Plastic Trays: Many plastic trays are recyclable, but this depends on the type of plastic and local recycling facilities. Check the recycling symbol on the tray to determine its plastic type and consult local guidelines. Ensure the tray is empty and clean before recycling.

- Foam Trays: Polystyrene foam (Styrofoam) trays are often not recyclable and should be disposed of in the general waste stream. However, regulations vary by location; some areas have banned or restricted foam use.

- Aluminum Trays: Aluminum trays are generally recyclable. Rinse the tray to remove food residue before recycling.

- Paperboard Trays: Paperboard trays can usually be recycled, provided they are not heavily soiled with food or grease. Check local guidelines for paper recycling requirements.

- Composting: Some trays are made from compostable materials. If a tray is certified compostable, it can be disposed of in a commercial composting facility or, in some cases, a home compost pile. Always follow the manufacturer’s instructions.

- General Waste: Trays that are not recyclable or compostable should be disposed of in the general waste stream. Ensure that lids are securely closed to contain food waste.

Importance of Following Safety Guidelines to Prevent Contamination

Adhering to safety guidelines is essential to prevent foodborne illnesses and maintain food quality. This includes both proper handling and disposal procedures.

- Preventing Cross-Contamination: Use separate trays and lids for raw and cooked foods to avoid cross-contamination. Always wash and sanitize trays thoroughly after use.

- Maintaining Food Temperature: Keep hot foods hot and cold foods cold to inhibit bacterial growth. Use insulated trays or containers for temperature control during transport.

- Avoiding Physical Hazards: Ensure trays and lids are free from cracks, chips, or other damage that could contaminate food or pose a safety risk.

- Compliance with Regulations: Following safety guidelines helps to comply with food safety regulations and standards. This protects consumers and prevents legal issues.

- Promoting Food Safety Culture: Implementing and enforcing safety guidelines creates a culture of food safety within a food service operation or household.

Comparison of Competitors

The food tray with lid market is competitive, with numerous manufacturers vying for market share. Understanding the strengths and weaknesses of different suppliers is crucial for making informed purchasing decisions. This section provides a comparative analysis of leading competitors, examining their product features, pricing strategies, and market positioning.

Comparative Feature Analysis

A comprehensive feature comparison allows for an objective evaluation of different food tray offerings. The table below provides a comparative analysis of key features and benefits across several prominent manufacturers. This table should be read carefully as it is a great example of how to compare the features and benefits of food trays from different manufacturers.

| Manufacturer | Material Options | Lid Features | Sustainability Initiatives | Unique Selling Proposition |

|---|---|---|---|---|

| Company A |

|

|

|

Wide range of sizes and configurations, catering to diverse food service needs. |

| Company B |

|

|

|

Commitment to sustainable packaging solutions, targeting environmentally conscious consumers. |

| Company C |

|

|

|

Cost-effective solutions for high-volume food service operations. |

Product Offering Differentiation

The product offerings of leading competitors vary significantly, reflecting diverse market strategies. Understanding these differentiations is critical for selecting the food tray with lid that best aligns with specific business needs.Company A focuses on a broad product portfolio, offering various materials and lid designs to accommodate a wide range of food types and applications. Their emphasis is on versatility and catering to diverse customer requirements.

They may also provide custom printing options for branding purposes.Company B differentiates itself through a strong commitment to sustainability. Their product offerings primarily consist of biodegradable and compostable food trays with lids. This positioning attracts environmentally conscious consumers and businesses seeking eco-friendly packaging alternatives. Company B’s pricing is often slightly higher due to the cost of sustainable materials.Company C concentrates on providing cost-effective solutions, particularly for high-volume food service operations.

They offer a range of standard tray sizes and lid designs, often prioritizing affordability and functionality. They may have established supply chain relationships that enable them to offer competitive pricing.

Pricing Strategy Contrast

Pricing strategies employed by major suppliers of food trays with lids differ based on factors like material costs, manufacturing processes, and target markets. Examining these strategies provides insights into the overall cost structure and value proposition of each competitor.Company A’s pricing strategy is generally competitive, offering a balance between quality and affordability. Their pricing is influenced by the materials they use.

The pricing also reflects their broad market reach and ability to negotiate favorable terms with suppliers.Company B often employs a premium pricing strategy, reflecting the higher costs associated with sustainable materials such as PLA. This approach is justified by the value proposition of eco-friendliness and the willingness of environmentally conscious consumers to pay a premium.Company C typically adopts a cost-leadership strategy, focusing on offering the lowest possible prices.

This strategy is achieved through efficient manufacturing processes, standardized designs, and bulk purchasing of materials. This positioning makes them attractive to price-sensitive customers and high-volume users.

Case Studies

Food trays with lids have revolutionized food service and packaging across various industries. Examining real-world examples provides valuable insights into their practical applications and the benefits they offer. These case studies highlight the positive impact of these trays on efficiency, waste reduction, and overall operational improvements.

Restaurant Chain: Streamlining Takeout Operations

A major fast-casual restaurant chain implemented food trays with lids across its takeout and delivery services. This decision significantly improved their operational efficiency.

- Challenge: The restaurant chain struggled with food spillage and leakage during takeout and delivery, leading to customer dissatisfaction and food waste.

- Solution: The chain switched to food trays with tightly sealed lids. These trays were designed to withstand temperature variations and maintain food integrity during transit.

- Results:

- Reduced food spillage by 80%, leading to fewer complaints and increased customer satisfaction.

- Minimized food waste, resulting in cost savings and improved sustainability efforts.

- Improved the speed and efficiency of takeout order preparation, as food could be quickly assembled and sealed.

Hospital Cafeteria: Enhancing Patient Meal Service

A large hospital cafeteria adopted food trays with lids to improve patient meal service and ensure food safety.

- Challenge: The hospital faced challenges in maintaining food temperatures and preventing contamination during meal distribution to patients.

- Solution: The cafeteria selected insulated food trays with lids. These trays were designed to maintain the temperature of hot and cold items separately, ensuring food safety and patient satisfaction.

- Results:

- Improved patient satisfaction with meal quality and temperature.

- Reduced the risk of foodborne illnesses due to better temperature control.

- Streamlined meal distribution, allowing for faster and more efficient service.

Catering Company: Enhancing Presentation and Delivery

A catering company adopted food trays with lids to improve the presentation and delivery of their meals.

- Challenge: The catering company needed a way to present food attractively while ensuring it remained fresh and protected during transport to events.

- Solution: The company began using clear, aesthetically pleasing food trays with lids that allowed for attractive food presentation while providing a secure seal.

- Results:

- Enhanced the visual appeal of the food, contributing to a positive customer experience.

- Protected food from contamination and maintained freshness during transit.

- Improved the efficiency of meal setup at events, as food could be pre-portioned and sealed before delivery.

Final Thoughts

In conclusion, food trays with lids are far more than simple containers; they are integral components of the food industry, evolving with consumer demands and environmental considerations. From selecting the right materials and designs to understanding the regulations and standards, the choices made around food trays with lids significantly impact food safety, waste reduction, and operational efficiency. As technology and sustainability continue to advance, food trays with lids will undoubtedly adapt and innovate, playing a vital role in shaping the future of how we store, transport, and enjoy food.