Kraft Foods Woburn MA offers a fascinating glimpse into the operations of a major food manufacturer. This analysis will explore the history, products, and impact of the Kraft Foods facility located in Woburn, Massachusetts. We’ll delve into the facility’s evolution, from its inception to its current status, and examine its role within the broader Kraft Foods network.

This overview will encompass a range of aspects, including product lines, employment figures, community involvement, manufacturing processes, sustainability initiatives, supply chain logistics, and future prospects. Through this comprehensive examination, we aim to provide a detailed understanding of the Kraft Foods Woburn MA facility’s significance within the food industry and its impact on the local community.

Kraft Foods Woburn, MA: Kraft Foods Woburn Ma

Kraft Foods’ presence in Woburn, Massachusetts, has been a significant aspect of the local economy and food industry for many years. The facility’s operations have evolved, adapting to changing market demands and consumer preferences. This overview provides a concise history and current status of the Kraft Foods location in Woburn.

History of Kraft Foods in Woburn, MA

Kraft Foods’ establishment in Woburn, MA, marks a chapter in the company’s broader North American presence. The specific details of its initial founding and early operational phases are important to understand.Kraft Foods’ presence in Woburn, MA, can be traced back to a specific period. The initial establishment involved the construction of a manufacturing and distribution facility. The location was strategically chosen for its proximity to transportation networks and access to a skilled workforce.

Early operations likely focused on producing a limited range of products, catering to the demands of the regional market. The company expanded its capabilities over time, leading to an increase in production capacity and the diversification of product lines. The facility underwent several expansions and upgrades to accommodate the growth. These developments often reflected advancements in food processing technology and changes in consumer tastes.

Expand your understanding about festival food shopping list with the sources we offer.

Products Manufactured or Distributed

The Woburn facility’s product portfolio has changed over time. The facility played a crucial role in supplying various products to the market.Kraft Foods Woburn, MA, has manufactured and distributed a range of food products. The product line has been adjusted over time to reflect the changing consumer demands and company strategies. The following are examples of the products that the facility might have handled:

- Processed cheese products: These could include various types of cheese slices and cheese spreads.

- Ready-to-eat meals: Production might have involved the manufacturing and packaging of pre-made meals.

- Sauces and dressings: The facility could have been involved in producing salad dressings and other sauces.

- Condiments: Production of items such as ketchup and mustard.

Current Operational Status

The operational status of the Kraft Foods facility in Woburn, MA, is subject to change. It is crucial to verify the most recent information to understand the facility’s current role.The Kraft Foods facility in Woburn, MA, has undergone changes in its operational status over the years. Information regarding the current state of the facility is crucial. As of the latest available information, the Woburn location has been involved in a transition.

This includes changes in manufacturing scope, workforce adjustments, or complete closure. The specifics of these changes are dependent on factors such as market conditions, company restructuring efforts, and the strategic alignment of the facility with the broader Kraft Heinz portfolio. The facility’s operations may have been consolidated with other locations or possibly discontinued. The current operational status can be determined through direct contact with Kraft Heinz or through credible news sources.

Kraft Foods Woburn, MA: Kraft Foods Woburn Ma

The Kraft Foods facility in Woburn, Massachusetts, plays a significant role in the company’s overall manufacturing and distribution network. This location contributes to the production of various food products, impacting the availability of these items in the northeastern United States and beyond. The Woburn facility’s operations reflect Kraft Heinz’s commitment to providing a wide range of food choices to consumers.

Kraft Foods Woburn, MA: Products and Brands, Kraft foods woburn ma

The Kraft Foods Woburn, MA, facility manufactures a selection of well-known brands and product lines, catering to diverse consumer preferences. This production supports Kraft Heinz’s position in the food industry, ensuring that popular items are readily available to consumers.

- Kraft Macaroni & Cheese: A staple product for many families, known for its iconic cheesy flavor and convenience.

- Velveeta: A processed cheese product used in various recipes and snacks, valued for its smooth texture and melting properties.

- Kraft Singles: Individually wrapped slices of processed cheese, popular for sandwiches and quick meals.

- Philadelphia Cream Cheese: A widely used cream cheese product for both sweet and savory applications.

The primary ingredients used in the production at the Kraft Foods Woburn, MA, facility are essential to the characteristic flavors and textures of its products. These ingredients are carefully sourced and processed to meet quality standards.

- Macaroni & Cheese: Ingredients include pasta, cheese (often a blend of cheddar and other cheeses), milk, and various seasonings.

- Velveeta: Key ingredients consist of milk, whey, cheese cultures, and emulsifiers.

- Kraft Singles: Ingredients typically include milk, cheese cultures, whey protein concentrate, and food colorings.

- Philadelphia Cream Cheese: The main components are milk, cream, cheese cultures, and stabilizers.

The packaging methods and materials used for Kraft Foods products at the Woburn facility are crucial for preserving freshness, ensuring product safety, and conveying brand information. These packaging choices are made considering factors like shelf life, transportation, and consumer convenience. The following table provides details on the packaging for a selection of products manufactured at the Woburn facility.

| Product | Packaging Method | Packaging Material | Notes |

|---|---|---|---|

| Kraft Macaroni & Cheese | Carton, single-serving pouch | Paperboard carton, plastic film pouch (polypropylene or similar) | Carton provides structure, pouch protects contents from moisture and air. |

| Velveeta | Box, foil-lined wrapper | Paperboard box, foil-lined plastic film | Box provides protection, foil-lined wrapper maintains freshness and prevents light exposure. |

| Kraft Singles | Individually wrapped slices, multi-pack box | Plastic film (polyethylene or similar), paperboard box | Individual wrapping preserves each slice, box provides organization and protection. |

| Philadelphia Cream Cheese | Tub, foil seal, lid | Plastic tub (polypropylene or similar), aluminum foil seal, plastic lid | Tub provides structural support, foil seal maintains freshness, lid ensures reusability. |

Kraft Foods Woburn, MA: Kraft Foods Woburn Ma

Kraft Foods’ presence in Woburn, Massachusetts, has been a significant factor in the local economy and community for many years. The facility provides employment opportunities and actively participates in initiatives that benefit the area. This section will delve into the specifics of employment, community involvement, and the overall economic impact of Kraft Foods on Woburn.

Employment at Kraft Foods Woburn, MA

The Kraft Foods facility in Woburn offers a variety of employment opportunities, contributing to the local job market. The types of roles available span several areas of operation.The facility employs a significant number of individuals in various capacities.

- Manufacturing and Production: These roles involve the direct creation of food products, including operation of machinery, quality control, and packaging. The positions require a range of skills, from basic machine operation to more specialized technical expertise.

- Warehouse and Logistics: These positions are crucial for the storage, management, and distribution of raw materials and finished goods. They often involve tasks such as inventory management, order fulfillment, and transportation coordination.

- Research and Development: Kraft Foods, like many large food manufacturers, invests in research and development to create new products and improve existing ones. These roles require a background in food science, chemistry, or related fields.

- Administrative and Support Staff: This category includes roles in human resources, finance, marketing, and other administrative functions necessary to support the facility’s operations. These positions are essential for the smooth functioning of the facility.

Community Outreach and Initiatives

Kraft Foods in Woburn actively participates in community outreach programs, demonstrating its commitment to corporate social responsibility. The company supports local initiatives and organizations.Kraft Foods’ community involvement is multifaceted, encompassing various types of support:

- Donations and Sponsorships: The company often provides financial support or in-kind donations to local charities, schools, and community events. This can include contributions to food banks, educational programs, and cultural activities.

- Volunteer Programs: Kraft Foods may encourage its employees to participate in volunteer activities, such as community clean-up drives or fundraising events. Employee volunteerism strengthens the company’s ties with the community.

- Partnerships with Local Organizations: The company may collaborate with local organizations to address specific community needs, such as food security or educational initiatives. These partnerships often involve long-term commitments.

Economic Impact on Woburn

Kraft Foods’ presence in Woburn has a measurable economic impact on the community, including tax revenue and partnerships with local businesses. The facility’s operations generate income and contribute to the local economy.The economic influence is realized through multiple channels:

- Tax Revenue: The Kraft Foods facility contributes to the city’s tax base through property taxes, payroll taxes, and other forms of taxation. This revenue supports local government services.

- Local Partnerships: The company often partners with local businesses for supplies, services, and other needs. This fosters economic growth within the Woburn area.

- Job Creation: The facility’s employment opportunities provide income for residents and contribute to the overall employment rate in Woburn. This has a ripple effect, as employees spend their earnings in the local economy.

- Infrastructure and Development: The presence of a large employer like Kraft Foods can also influence local infrastructure and development. For example, the company’s needs might spur improvements in transportation or utilities.

Kraft Foods Woburn, MA: Kraft Foods Woburn Ma

The Kraft Foods facility in Woburn, MA, plays a significant role in the production and distribution of various food products. This section focuses on the manufacturing processes, technologies, and quality control measures implemented at the Woburn location, providing insights into how Kraft Foods ensures the consistent quality and safety of its products.

Manufacturing Processes at Kraft Foods Woburn, MA

The Woburn facility likely employs a variety of manufacturing processes depending on the specific products manufactured there. These processes generally involve several key stages, including ingredient handling and preparation, processing, packaging, and distribution. Specific examples include the mixing of ingredients, cooking, or baking, and the filling and sealing of packaging.

Technologies and Equipment Used in Production

The Woburn facility utilizes advanced technologies and equipment to ensure efficient and high-quality production. This includes automated processing lines, sophisticated mixing and blending equipment, and advanced packaging systems. The automation contributes to consistent product quality and allows for high production volumes.

Quality Control Procedures and Standards

Kraft Foods Woburn, MA, adheres to rigorous quality control procedures to maintain product safety and consistency. These procedures are essential for meeting regulatory requirements and consumer expectations. The following is a bulleted list of quality control procedures and standards likely employed at the facility:

- Ingredient Sourcing and Inspection: Incoming ingredients undergo thorough inspection to ensure they meet quality and safety standards. This includes verifying ingredient specifications, testing for contaminants, and ensuring proper storage and handling.

- Process Monitoring: Throughout the manufacturing process, critical control points (CCPs) are monitored to ensure adherence to established parameters. This may involve monitoring temperature, pressure, and other variables that can affect product quality and safety.

- Equipment Calibration and Maintenance: Regular calibration and maintenance of equipment are performed to ensure accuracy and reliability. This helps to prevent errors and ensure consistent product quality.

- Product Testing: Finished products are tested for various parameters, including taste, texture, appearance, and nutritional content. These tests help to ensure that products meet quality specifications and consumer expectations.

- Packaging and Labeling Verification: Packaging and labeling are carefully verified to ensure accuracy and compliance with regulatory requirements. This includes checking for correct weight, labeling information, and proper sealing.

- Hygiene and Sanitation Protocols: Strict hygiene and sanitation protocols are followed throughout the facility to prevent contamination. This includes regular cleaning and sanitizing of equipment and work areas.

- Employee Training: Employees are trained on quality control procedures and standards to ensure they understand their roles and responsibilities. This includes training on food safety, hygiene, and proper handling of ingredients and products.

- Traceability Systems: Traceability systems are in place to track ingredients and products throughout the supply chain. This allows for quick identification and response to any potential quality or safety issues.

Kraft Foods Woburn, MA: Kraft Foods Woburn Ma

Kraft Foods, a well-established name in the food industry, has a significant presence in Woburn, Massachusetts. This facility, like other Kraft locations, operates with a focus on efficient production and responsible resource management. The company recognizes the importance of sustainability in its operations, aiming to minimize its environmental impact while producing high-quality food products.

Sustainability and Environmental Practices

Kraft Foods Woburn, MA, has implemented several sustainability initiatives to reduce its environmental footprint. These practices encompass various aspects of the facility’s operations, from energy consumption and waste management to water usage and supply chain considerations. The following points highlight key areas of focus:

- Energy Efficiency: The facility strives to reduce energy consumption through various measures. This includes the implementation of energy-efficient equipment, such as LED lighting and optimized HVAC systems. Regular energy audits are conducted to identify areas for improvement and ensure ongoing efficiency.

- Waste Reduction and Recycling: Kraft Foods Woburn actively promotes waste reduction and recycling programs. The facility has implemented comprehensive recycling programs for various materials, including paper, cardboard, plastics, and metals. They also work to minimize food waste throughout the production process, exploring options like composting and donating surplus food to local organizations.

- Water Conservation: Water usage is carefully managed at the Woburn facility. This involves implementing water-efficient equipment and processes. The company also monitors water consumption closely to identify opportunities for further reduction and ensure responsible water management.

- Sustainable Sourcing: Kraft Foods is committed to sourcing ingredients and materials from sustainable sources. This includes working with suppliers who adhere to responsible environmental practices. The company also aims to reduce its carbon footprint by optimizing its supply chain and transportation methods.

Certifications and Awards

Kraft Foods Woburn, MA, may have obtained certifications and received awards that recognize its environmental performance. These accolades demonstrate the facility’s commitment to sustainability and its efforts to minimize its impact on the environment. While specific certifications and awards can change over time, the following examples illustrate the types of recognition the facility might have received:

- LEED Certification: The facility may have pursued Leadership in Energy and Environmental Design (LEED) certification for its buildings. LEED certification recognizes buildings designed and constructed with sustainability in mind.

- ISO 14001 Certification: The facility may have obtained ISO 14001 certification, which signifies that it has implemented an environmental management system. This system helps the company to identify and manage its environmental impacts.

- Local Environmental Awards: The Woburn facility could be recognized by local organizations or government agencies for its sustainability efforts. These awards may acknowledge specific initiatives, such as waste reduction programs or energy efficiency projects.

Illustrations and Images Related to Sustainability Practices at Kraft Foods Woburn, MA:

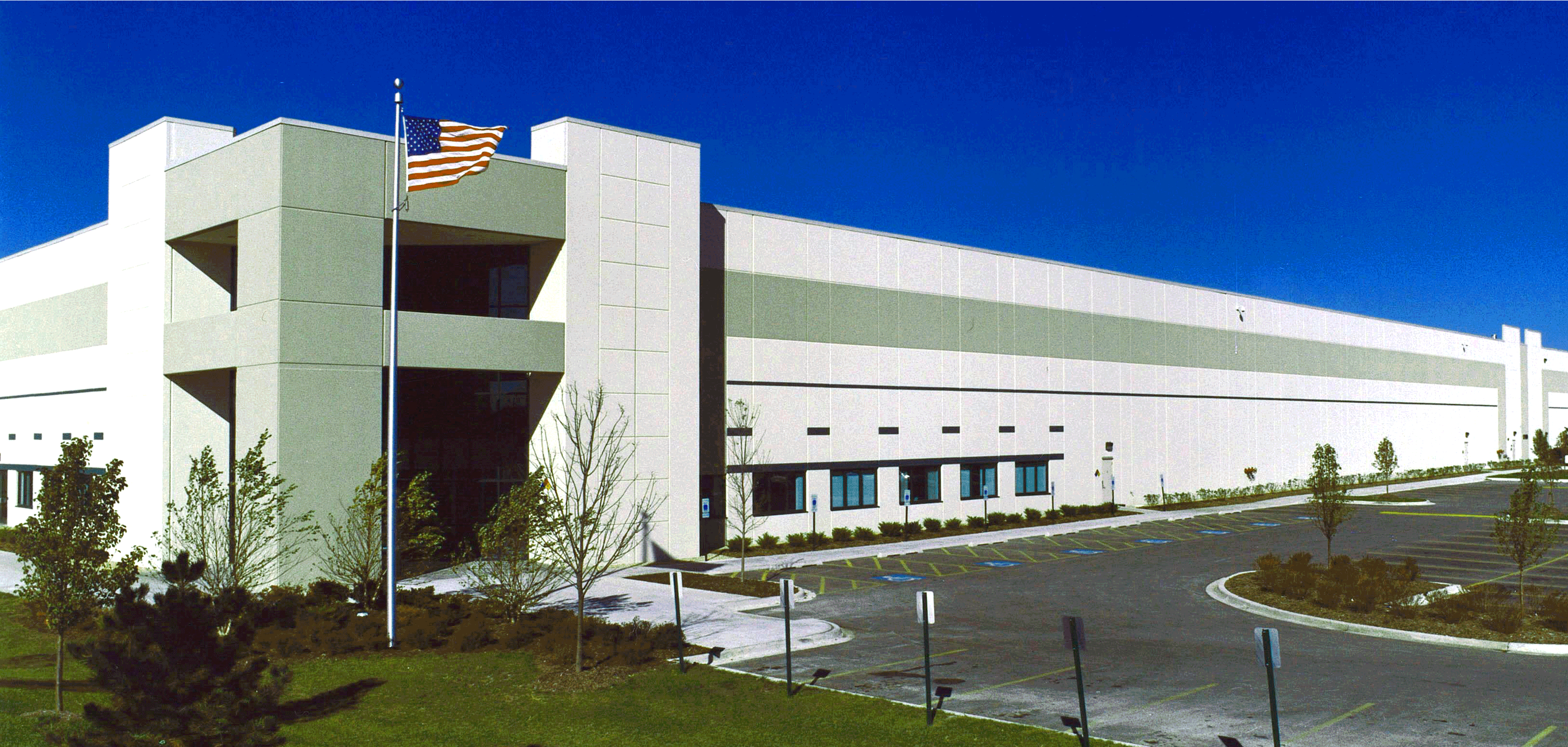

Image 1: A photograph depicting the exterior of the Kraft Foods Woburn facility. The image showcases the building’s architecture and design, with a focus on features that contribute to sustainability, such as solar panels on the roof or a green roof. The surrounding landscape may include native plants and trees, demonstrating the facility’s commitment to environmental stewardship.

Image 2: An illustration or photograph showing a recycling station within the Kraft Foods Woburn facility. The image highlights clearly labeled bins for various recyclable materials, such as paper, plastic, and metal. Employees are depicted actively participating in the recycling program, emphasizing the importance of employee involvement in waste reduction efforts.

Image 3: A diagram or infographic illustrating the facility’s water conservation efforts. The graphic may depict the different stages of water usage within the facility, from intake to wastewater treatment. It may also highlight water-efficient equipment and processes, such as low-flow fixtures and closed-loop cooling systems, with associated water savings data.

Image 4: A photograph showing the installation of energy-efficient lighting systems, such as LED lights, within the Kraft Foods Woburn facility. The image illustrates the use of advanced lighting technology to reduce energy consumption. Workers are shown installing the lights, emphasizing the facility’s commitment to modernizing its infrastructure.

Image 5: A photograph showing employees participating in a community outreach program related to environmental sustainability. This could be a volunteer event focused on environmental cleanup or a community garden initiative. The image showcases the company’s commitment to engaging with the local community and promoting environmental awareness.

Kraft Foods Woburn, MA: Kraft Foods Woburn Ma

The Kraft Foods facility in Woburn, MA, plays a crucial role in the production and distribution of various food products. Understanding the intricacies of its supply chain and logistics network is essential to appreciating its operational efficiency and impact on the market. This discussion will delve into the supply chain, distribution methods, and transportation strategies employed by Kraft Foods at its Woburn location.

Kraft Foods Woburn, MA: Supply Chain and Logistics

The supply chain and logistics operations at Kraft Foods Woburn, MA, are complex, involving the procurement of raw materials, processing, packaging, warehousing, and distribution. Efficient management of these elements ensures the timely delivery of products to consumers while minimizing costs and maintaining product quality.The supply chain begins with sourcing raw materials, such as ingredients and packaging materials. These materials are then transported to the Woburn facility, where they undergo processing and manufacturing.

Finished products are then packaged and stored in warehouses before being distributed to various retail locations. The entire process is carefully coordinated to optimize efficiency and reduce waste.

Distribution Methods from Woburn

Kraft Foods utilizes a multi-faceted distribution network to deliver its products from the Woburn facility. This network is designed to reach a wide range of customers, including grocery stores, supermarkets, and other retailers.The primary methods of distribution include:

- Direct Store Delivery (DSD): This method involves delivering products directly from the Woburn facility to individual stores. DSD is often used for products with shorter shelf lives or those requiring frequent restocking, such as certain dairy products or refrigerated items. This allows for better inventory management and fresher products for consumers.

- Distribution Centers: Kraft Foods also utilizes distribution centers, strategically located throughout the region. Products are shipped from the Woburn facility to these centers, which then distribute them to various retail locations. This approach provides economies of scale and allows for efficient handling of large volumes of products.

- Third-Party Logistics (3PL) Providers: Kraft Foods may partner with 3PL providers to manage certain aspects of its distribution network. These providers offer specialized services, such as warehousing, transportation, and order fulfillment. This allows Kraft Foods to focus on its core competencies while leveraging the expertise of logistics professionals.

Transportation Methods by Product Type

The transportation methods employed by Kraft Foods Woburn, MA, vary depending on the type of product being shipped, the distance to be covered, and the required delivery time.Different product types are transported using different methods:

- Refrigerated Products: Products requiring temperature control, such as dairy items and certain processed foods, are transported in refrigerated trucks. These trucks maintain a consistent temperature to ensure product safety and quality. The use of refrigerated transport is crucial for preserving the freshness and extending the shelf life of perishable goods.

- Dry Goods: Non-perishable products, such as crackers, cookies, and canned goods, are typically transported in dry vans or trailers. These trailers provide a protected environment for the products during transit.

- Bulk Ingredients: Large quantities of ingredients, such as sugar or flour, may be transported in bulk carriers, such as tanker trucks or railcars. This method is cost-effective for handling large volumes and minimizes the need for packaging.

- Intermodal Transportation: For long-distance shipments, Kraft Foods may utilize intermodal transportation, which combines different modes of transport, such as truck, rail, and ship. This approach can be more cost-effective and environmentally friendly than using a single mode of transport. For example, products might be transported by truck to a rail yard, then by rail across the country, and finally by truck to their final destination.

Kraft Foods Woburn, MA: Kraft Foods Woburn Ma

Kraft Foods’ facility in Woburn, Massachusetts, has a rich history and plays a significant role in the company’s operations. As the food industry evolves, the Woburn location is poised for future developments to maintain its competitiveness and meet changing consumer demands. This section will explore the anticipated changes and advancements planned for the Kraft Foods Woburn, MA, facility over the next few years.

Future Prospects and Developments

Kraft Foods Woburn, MA, is planning several strategic initiatives to enhance its operational capabilities and product offerings. These plans include potential expansions, technology upgrades, and the introduction of new products. The following details Artikel the key areas of focus.

Planned Expansions and Renovations

Kraft Foods is continually assessing the needs of its facilities to optimize production and efficiency. While specific details regarding expansions are often proprietary, the company generally considers the following factors when making investment decisions:

- Capacity Optimization: Increasing production capacity to meet growing market demands for existing product lines. This could involve adding new processing lines, expanding warehouse space, or upgrading existing equipment. An example of this is seen at Kraft Heinz’s facility in Holland, Michigan, which underwent a significant expansion in 2021 to increase its cheese production capacity.

- Efficiency Improvements: Renovations and upgrades designed to streamline operations, reduce waste, and improve overall productivity. This may involve implementing automation technologies, optimizing workflow processes, and modernizing infrastructure.

- Sustainability Initiatives: Integrating sustainable practices into the facility’s design and operations. This could include energy-efficient upgrades, water conservation measures, and waste reduction programs. Kraft Heinz has demonstrated a commitment to sustainability through initiatives like reducing greenhouse gas emissions and water usage across its global operations.

Potential New Products and Technologies

Kraft Foods is known for its innovation in the food industry, constantly developing new products and incorporating cutting-edge technologies. The Woburn facility may be involved in the introduction of these innovations.

- New Product Development: The facility could potentially be used for the production of new product lines. This could include items that cater to evolving consumer preferences, such as plant-based alternatives, healthier options, or products with unique flavor profiles.

- Technological Advancements: Implementing advanced technologies to improve efficiency and product quality. This may include:

- Automation: Utilizing robotics and automated systems for various stages of the production process, from packaging to quality control. For example, in its manufacturing plants, Nestle has adopted automation to increase efficiency and reduce labor costs.

- Data Analytics: Employing data analytics to optimize production processes, predict demand, and improve supply chain management.

- Advanced Packaging: Utilizing innovative packaging materials and techniques to enhance product shelf life, reduce waste, and improve consumer convenience.

Timeline of Anticipated Events (Next Five Years)

The following is a generalized timeline of potential events at the Kraft Foods Woburn, MA, facility. Actual timelines may vary depending on market conditions and strategic priorities.

- Year 1-2: Focus on optimizing existing operations. This may include minor equipment upgrades, process improvements, and potential adjustments to production schedules to meet current demand.

- Year 2-3: Evaluate the feasibility of potential expansions. This may involve conducting market analysis, assessing facility needs, and developing preliminary plans for future growth.

- Year 3-4: Begin implementation of planned renovations or expansions, depending on the outcomes of the evaluation phase. This may include construction, equipment installation, and staff training.

- Year 4-5: Integrate new technologies and processes. This could involve the launch of new product lines, the implementation of advanced automation systems, and further optimization of production processes.

Last Word

In conclusion, the Kraft Foods Woburn MA facility represents a significant player in the food industry, demonstrating a complex interplay of manufacturing, community engagement, and sustainability efforts. From its historical roots to its future aspirations, the facility’s evolution reflects the dynamic nature of the food production landscape. Its impact on the local economy and environment is a testament to the importance of responsible corporate practices and ongoing innovation within the food sector.